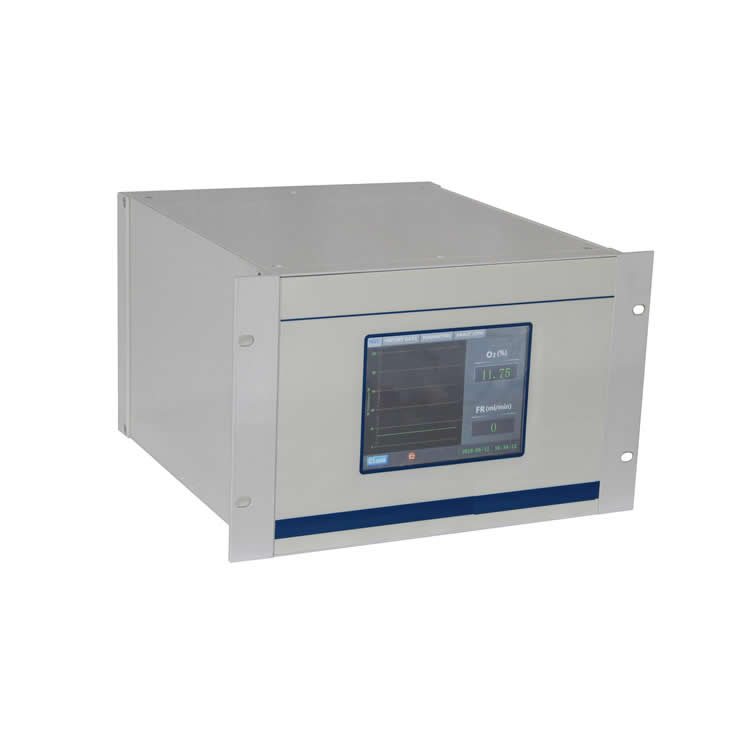

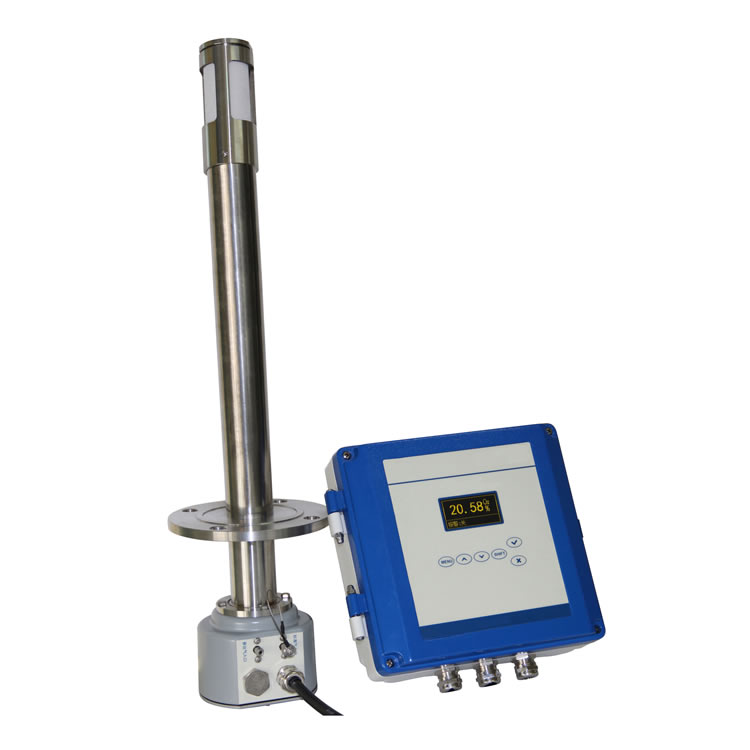

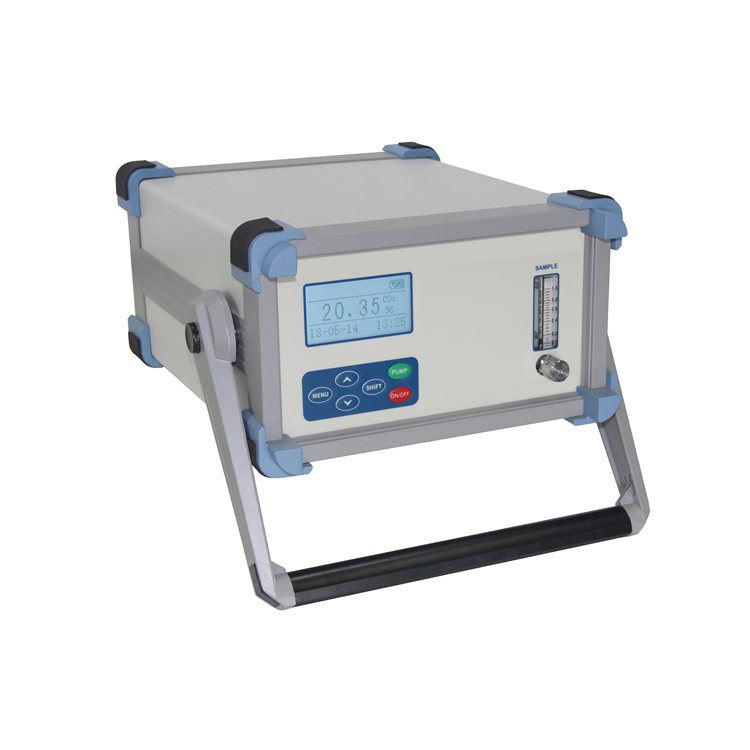

Oxygen analysis system uses imported special materials to effectively absorb the toxic components in the sample gas and send them to the explosion-proof oxygen transmitter, thus ensuring the service life and accuracy of the explosion-proof oxygen transmitter. The user can control the corresponding nitrogen supply device by collecting the oxygen concentration value measured by the system, thereby reducing the concentration of flammable and explosive gas in the centrifuge and the reaction kettle, thereby providing safety for production.

Oxygen analysis system technical parameters:

Test principle | Fuel cell |

Display mode | 128×64 matrix dot LCD |

Test range | 0 ~ 5/10/25.00% O2

(Different ranges are available: trace or constant) |

Accuracy | ≤±1%FS |

Repeatability | ≤±1% |

Error | <±1.2%FS |

Response time | T90≤60S |

Analog output | 4~20mA.DC (non-isolated output, load resistance less than 500 ohms) 2-way programmable dry contact passive alarm output, contact maximum capacity 220VAC/2A |

Power supply | DC24V/0.5A |

Sample gas temperature | 0 ~ 50℃ |

Environment humidity | <80%RH |

Sampling mode | straight-through type |

Sampling pipeline | Φ6mm316L seamless stainless steel tube, PTFE tube |

Sample gas flow | 600 ~ 800ml/min |

Sample gas component | No strong corrosive gas, the amount of dust is less than 1mg/Nm3 |

Preprocessing level | Ⅰlevel |

Working pressure | 90~110KPa, Stabilized atmosphere (absolute pressure) |

Size | 213mm×315mm×155mm(H×W×D) |

Install Hole Cut | 135mm×80mm(H×W) |

Serving life | >24 months (under normal use) |

Install mode | Wall-mounted |

Explosion-proof grade | Exd IIB T4 |

Note | 1.The above technical parameters are written with constant oxygen as the standard. If you measure trace oxygen, please contact our company for relevant technical parameters. 2.Different ranges of oxygen transmitters can be equipped according to different field requirements, namely: trace oxygen system and constant oxygen system; 3.According to different field, The corresponding sampling system and the positive pressure, micro positive pressure and micro negative pressure sampling system can be designed. |

Disclaimer: The product introduction content (including product images, product descriptions, technical parameters, etc.) of this site is for reference only. As the update may not be timely, there will be some differences between the content and the actual situation. Please contact our sales staff to confirm. The information provided on this site does not constitute any offer or promise, and the company will improve and modify any information on the website from time to time without prior notice.